How Concrete Can Degrade Over Time

One of the most common forms of concrete degradation is called ‘concrete spalling’, where pieces or flakes of concrete fall away from a larger surface. This can be caused by water, salt and other aggressive agents that are trapped inside the concrete due to inadequate waterproofing or sealing methods.

Freezing and thawing cycles can also cause concrete degradation, as water expands and contracts within the material. This can lead to the formation of deep cracks or fissures in the concrete, reducing its strength. Alkali-aggregate reactions (AARs) are another form of degradation that occur when alkaline materials mix with certain types of aggregate and cause them to swell and break down.

The physical properties of concrete can be affected by the presence of sulfates in groundwater or soil. These cause chemical reactions that lead to further cracking and spalling in the concrete. In extreme cases, sulfate can attack and cause the concrete to completely crumble and fall apart.

Concrete can also be damaged by external forces such as a lack of maintenance or inappropriate application of pressure. For example, if a structure is overloaded beyond its carrying capacity, it can cause the concrete to crack and crumble.

Preventing and Repairing Concrete Degradation

The best way to protect your concrete structure against degradation is by using adequate waterproofing techniques, maintaining good drainage systems, and ensuring that all reinforcing steel bars are properly protected against corrosion. Make sure that your concrete is regularly inspected and that any repairs are carried out immediately.

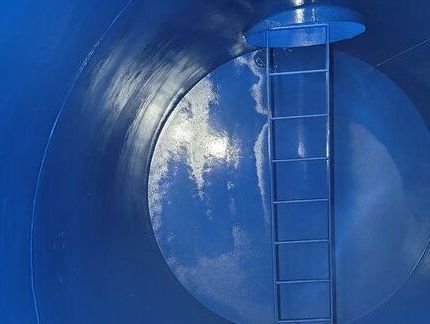

If you find that some of your concrete has already degraded, the team at Advanced Lining can help repair it. These resins are applied in layers over the affected area to form a waterproof seal and strengthen the existing concrete. They can also be used on new concrete to help protect it from future damage.

How Advanced Lining Helps Concrete Degradation

If you need concrete degradation repairs and restorations, Advanced Lining has all the right tools to fix infrastructures that are starting to crumble and crack, even in the harshest environments. Apply our OBIC products to your concrete structures in just minutes and with very minimal disruption to service and traffic flows. OBIC products uses a polyurea and polyurethane lining system that is proven to give long-lasting protection to even the most weathered structures. Catching the cracks and fissures early on will be the most beneficial for keeping your structures from breaking down and falling apart.