OUR PRODUCTS

Products

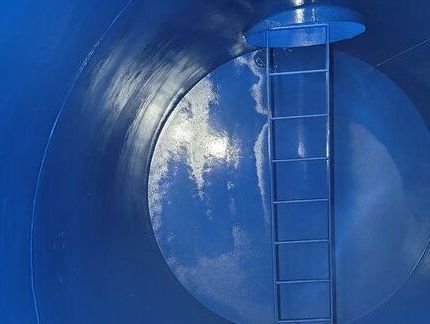

At Advanced Lining, we do not believe in the “one-size-fits-all” thought process. We believe that each and every application is unique and should be treated that way. With the full line of OBIC products available to us, we are able to install OBIC 5000 (structural polyurethane hybrid), OBIC 1000 (polyurea three layer system), OBIC 1200C (culvert liner) and OBIC 1100PW (potable water liner).

We believe in maximizing every dollar invested in your infrastructure, in order to do that we are happy to inspect your structure and make a recommendation as to which product fits best.

Structural Lining: OBIC 5000

OBIC 5000 is a 100% solids lining that reinstates structural integrity, provides infiltration control, corrosion resistance and asset life extension of concrete, steel, masonry and other substrates.

With its high abrasion and chemical resistance, adhesion and corrosion protection properties, it is ideally suited for the rehabilitation, renewal or proactive protection of wastewater, stormwater and industrial process water system structures.

Applications

Manholes, Lift Stations, Wet Wells, Grit Chambers, Culverts, Clarifiers, Junction Boxes, Secondary Containment, Tanks, Tunnels, Large Diameter Pipelines and more…

Benefits

- 1:1 Mix Ratio

- Quick Return to Service

- Easy Installation

- Can Be Applied Up to 250 Mils on a Single Deployment

- No Special Equipment Required

can be applied with a common dual proportioned system i.e. HXP-2/HVR or PHX-40, P2 or Fusion AP Spray Gun with reactor temp of 160ºF, 2100 PSI

Wastwater: OBIC 1000 (Polyurea)

Typical Installations

Manhole, Wet Wells, Pump Stations, Secondary Containment, Waterproofing, Industrial Coatings, Potable Water Containment, Water Treatment, Industrial Facilities, Food Processing Plant, Bridge Decks.

Product Highlights

OBIC Armor 1000 adheres extremely well to various properly prepared surfaces including metal, wood, concrete and fiber glass. Product highlights include:

- Excellent corrosion protection and chemical resistance

- Excellent impact resistance, even in sub-freezing weather

- High abrasion resistance for harsh environments

- Seamless monolithic waterproof membrane that is tough and durable

- Odorless, 100% Solid

- USGBC LEED, EQ Credit 4: Low-emitting VOC Compliant Materials

- Produced in an ISO 9001-2015 certified facility

Culvert: OBIC 1200C

Typical Installations

Repair and preventative maintenance for culverts and pipelines.

Product Highlights

OBIC Armor 1200C is a two-component polyurethane coating. When cured, it is highlighted by:

- High flexural modulus semi-structural monolithic coating for culvert and pipeline rehabilitation

- Excellent impact resistance and abrasion protection

- Formulated for rehabilitation of storm water, waste water, steel, concrete pipe repairs and other municipal or industrial applications.

- Recommended installation for structures 60” and larger in diameter

- Produced in an ISO 9001-2015 certified facility

Potable Water: OBIC 1100PW

Typical Installations

Potable Water Containment, Water Treatment, Industrial Facilities, Food Processing Plant, Bottling & Canning Plant.

Product Highlights

OBIC 1100PW adheres extremely well to various properly prepared surfaces including metal, wood, concrete and fiber glass. Potable water approved for ANSI 61 barrier material, product highlights include:

- UL certified ANSI/NSF 61 in specific colors

- Excellent corrosion protection and chemical resistance

- Excellent impact resistance, even in sub-freezing weather

- High abrasion resistance for harsh environments

- Seamless monolithic waterproof membrane that is tough and durable

- Odorless, 100% solids

- USGBC LEED, EQ Credit 4: Low-emitting VOC Compliant Materials

- Produced in an ISO 9001-2015 certified facility